The Walloon Region is a gold mine when it comes to innovative technology. Here is yet another example with PEPITe. Former spin-off from the University of Liège, founded in 2002 by Philippe Mack, the Liège based company has joined the playing field of international scale-ups with a successful fundraising campaign, raising 770,000 EUR.

In 2002, a UFO was born in the world of industry. A tool initially developed as part of a Master’s thesis, PEPITe moved away from research with the objective to revolutionize manufacturing. Big data, Artificial Intelligence (AI), Deep learning, data mining… While this technology was purely a thing of SCI-FI movies not so long ago, it now provides an answer to the question: “How to do more with less?” Green industry has become more than a necessity but an obligation. To survive in the world of tomorrow, manufacturers are investing. And for many reasons. Performance, reduction of energy consumption and CO2 emissions (and consequently carbon tax), predictive maintenance, recycling raw materials … These are all challenges that PEPITe addresses thanks to its intelligent solution to optimize industrial processes. With 20 years of experience, PEPITe now provides an answer to productivity and sustainability challenges in international manufacturing industries. Among its clients are major international names such as Prayon, Arcelor Mittal, Engie, Total, Jindal Films, John Cockerill, Galactic, Air Liquide and more.

After a search for funding that began two years ago, PEPITe is entering the last quarter of the year with a promising outlook. With solidly increased capital, the Liège based company is ready for scale up, on the way to sustainable growth.

“We have experienced an acceleration in digitization of manufacturing driven by the COVID crisis and moving to the cloud has become a necessity. Society and the industrial sector are now mature. We have recently signed several partnerships and important international contracts. PEPITe therefore needed funding to accelerate its growth and change gears!”

explains Philippe Mack, founder.

Fundraising is often synonymous with challenges, both human and strategic. A daring and necessary journey to enable growth. Surrounding yourself with the right people remains one of the keys to success. This was the case for PEPITe who found the rare gem, Sustinvest, an Antwerp investor “with a personal touch”.

“We needed financial resources, but above all human skills. We wanted a partner who would be personally involved and committed to supporting the company. We found an investor who was quickly convinced and did everything to make the transition as smooth as possible” says Philippe Mack.

It was in this context that Baptiste Fosséprez, an engineer by training, joined the Liège SME as CEO, in September 2021. After a career in telecommunications and media, Baptiste wishes to use his expertise to benefit “the greatest challenge facing mankind.”

“In recent years, I have become increasingly aware of climate change. So I looked for a way to put my skills and my experience to use for this cause. I found PEPITe offered great opportunity to create impact. Since my arrival, every day I have discover the human and intellectual value of the team. We have in our hands a fantastic product, convinced partners, confident investors. All the ingredients to make PEPITe a great success!”.

In terms of objectives, the tandem Baptiste Fosséprez and Philippe Mack wants to build solid foundations on which the company will grow. “Strong governance, a significant number of clients, a financially stable structure and the opportunity to test and validate new models with Belgian and international partners”. What’s the 5-year plan?

“Change leagues, maximize our impact. We aim to scale up. We intend to increase the workforce by five to reach around 100 people over five years. We want to be able to find a good mix between our software solution and client support projects. This combination allows us to stay close to the reality in manufacturing, to understand our users’ needs and the specificities of their process. The objective is to drive our solutions in the direction desired by users, combining simplicity and efficiency”.

“Natural resources have long been considered free and endless, as has waste. That’s no longer the case. A circular economy is being put in place, processes are becoming more complex and artificial intelligence has a role to play!”

adds Philippe Mack.

In 2018, PEPITe won the global Mining Lab Challenge organized by Nexa Resources in Brazil, up against big names in the sector such as IBM and Accenture. The company is using its Artificial Intelligence software at a zinc mine in Peru to optimize their kiln. The implementation project is underway.

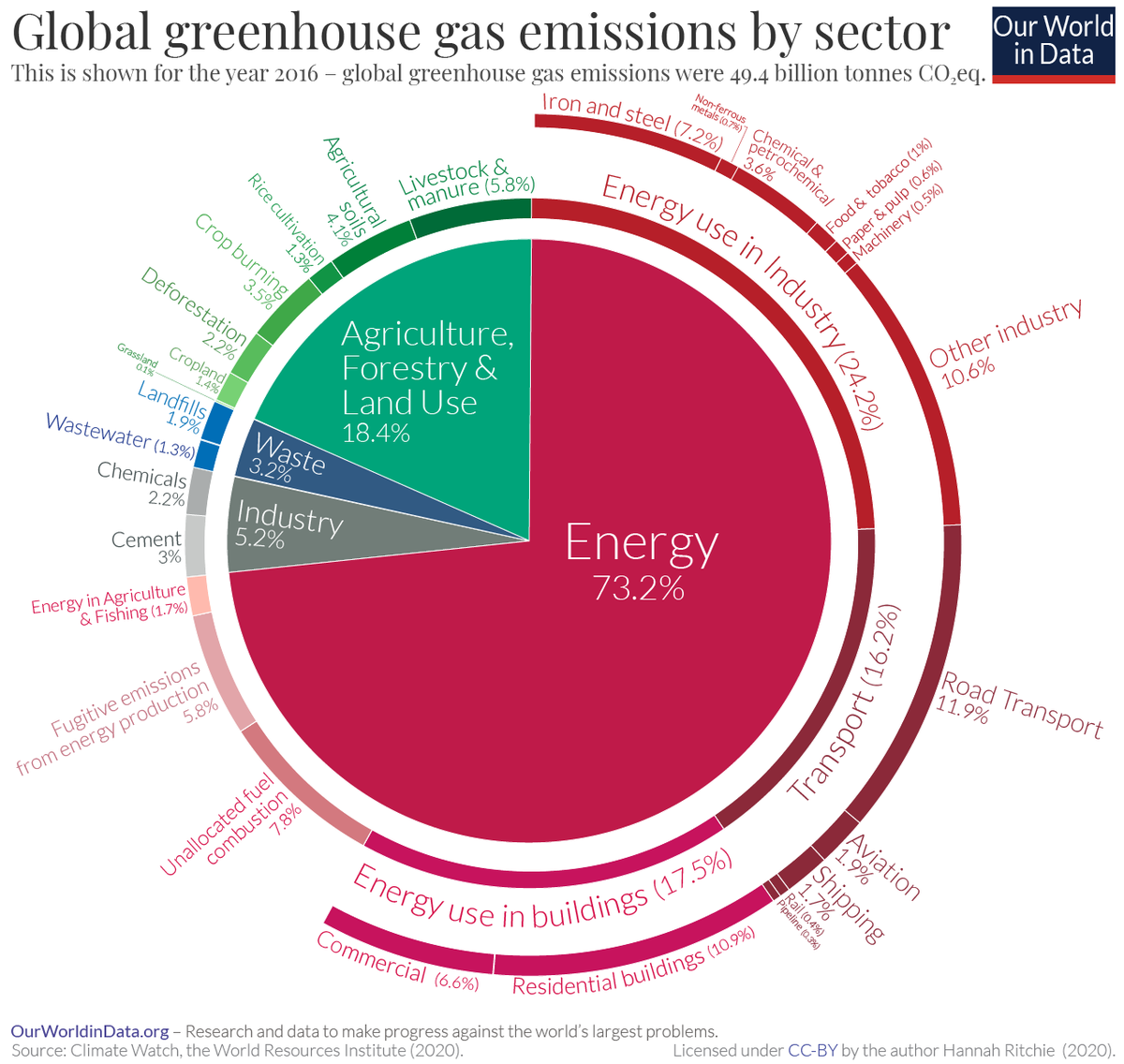

Manufacturing accounts for 30% of global greenhouse gas emissions (Climate Watch, the World Resources Institute, 2020, ourworldindata.org). PEPITe is able to optimize processes, leading to productivity gains and energy savings ranging from 5 to 30%, depending on the industry.

An engineer by training, Baptiste Fosséprez began his career at the European Space Agency. He then joined SES, a Luxembourg satellite telecommunications company. After ten years with SES, he branched out into the media industry by joining Ericsson. He then puts his corporate experience to use to help develop Freecaster, active in the field of online videos. Baptiste Fosséprez notably supported the Namur based SME during its acquisition by BCE (Broadcasting Center Europe, a subsidiary of the RTL group), where he was is responsible for development. He joined the Liège-based company PEPITe after the capital increase in September 2021.

As part of his final thesis, Philippe Mack, an electromechanical engineer, developed a data analysis and classification program. At that stage, the program was only applicable to research. With the desire and dream of “revolutionizing the world of industry”, Philippe Mack created the spin-off PEPITe in 2002 and gradually integrated production lines. Over 20 years, he has allowed PEPITe to accumulate the expertise and know-how to meet the challenges facing the biggest names in manufacturing.